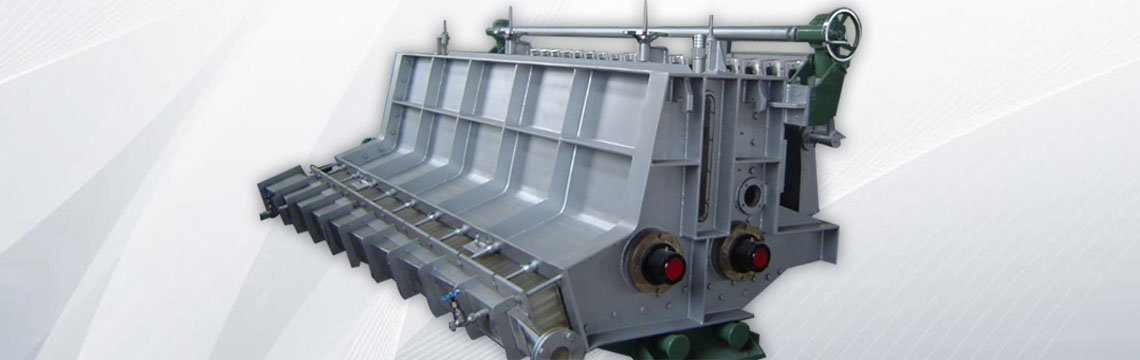

The Head Box consists of MS fabricated rectangular box with tapered tail end at the back side with Necessary stiffners. The front side is provided with SS Spring steel top and bottom slice lips for pulp flow. The total slice lip gap is adjusted by means of two worm gear box units connected to a common hand wheel. For individual micro profile corrections a number of stud and fly nut arrangement is provided along the top lip. A partition plate which can be moved upwards or downwards by means of a screw and wheel arrangements is provided for maintaining the level of pulp in the head box. A SS 304 shower is provided from the top for foam killing. At the bottom portion of the tail end a SS evener roll is fitted which is deiven by a chain and sprocket arrangement by means of a geared motor for avoiding slime formation and maintaining uniform distribution of flow. At the bottom cover of the tapered tailed end equal distance nozzles are provided for pulp inflow. These Nozzles are connected to the nozzles of a tapered SS manifold through flexible hose pipe. The whole head box is cladded inside with SS 304 sheet to avoid corrosion and slime formation. A platform is mounted at the front of head box for easy operating of slice.

- Plot No. 199/1/A, 2nd Phase, G.I.D.C, Vapi - 396195.

- Have a question call now (0260) 2420232, 2428388,

Head Box

Request a Quick Quote.

Fill out the form to get your quote. We guarantee safe and timley product delivery either for your personal travel or your products.